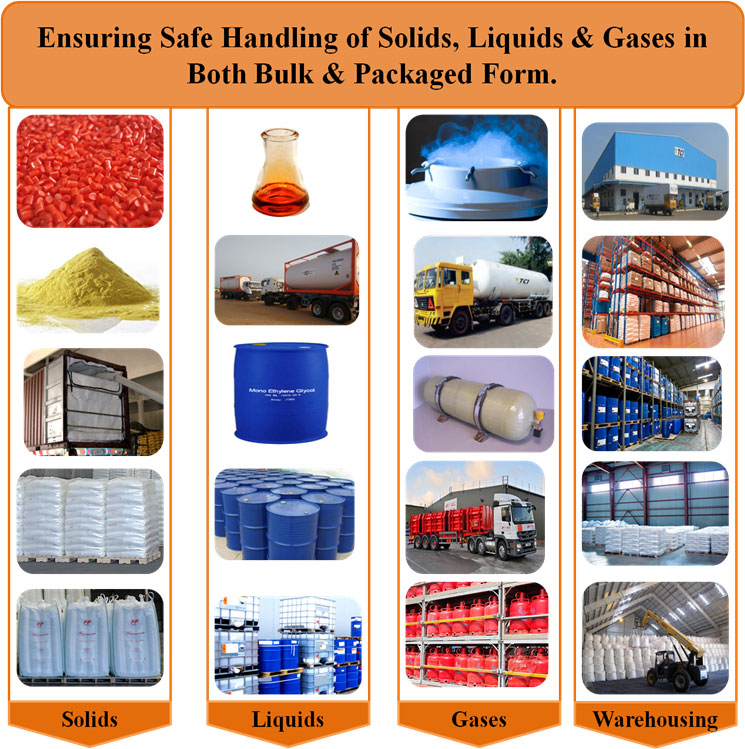

Chemical is a complex industry- products range from solids to liquids to gases and nature from Inert to Hazmat. The complexity of handling, storage and transportation is compounded with the fragmentation of the industry and lack of domestic standards.

We understand the unique requirement of chemical shipments. To ensure your cargo is safe and secure, TCI SCS provide micro and macro-level management of the Chemical Supply Chain. “Responsible Care” is the mantra of safe and environmentally conscious management as we seek to build global HSE standards in the Chemical industry.

Ensuring Safe movement of Liquid Chemicals

- Movement of Non-hazardous chemicals in polypropylene drums

- Weight capacity of each drum is around 230-250 ltrs

- 1 pallet can carry 4 drums

- Shrink wrap & lashing strap for the safety of the cargo

- Movement of Non-hazardous/hazardous chemicals in ISO Tanktainers

- TCI has both SS & MS ISO Tanktainers

- Weight carrying capacity of each Tanktainers is around 25-26k L

- These Tanktainers can be used both on Rail and Road

- The Tanktainers has side access and hard open top

- Flexi tank is designed for the transportation of non-hazardous chemicals in 20' ISO containers

- It is conceived as expendable packing for the transportation of liquid

- The weight carrying capacity of Flexitanks varies from 10-24k L

- Flexi tanks offer a dynamic, flexible, safe and cost effective solution for all bulk liquid transport requirements

Ensuring Safe movement of Dry Chemicals

- Movement of dry chemicals in Jumbo bag

- Weight carrying capacity of each Jumbo bag is around 1.5 ton

- Its precise design make these suited for a wide range of end products like Soda Ash, Carbon Black, Dyes, Cement, Non flammable Chemicals and others

- Dry bulk movements in “Container liners” for Bulk handling of cargo in 40’ & 20’ containers

- It’s a protective shield between the bulk cargo and container walls, ensuring all benefits of advanced bulk packaging

- The type of products typically transported by this method should be dry &free flowing with generally particle sizes being less than 10mm

- The weight carrying capacity is around 22-28 MT

Ensuring Safe movement of Gases

- The movement of gases in done in customized Stainless steel for both

- - Cryogenic gases

- - Specialty Gases

- CCOE Approved

- Drivers equipped with Dangerous Good license

- Specially designed Pressure Circuit to maintain the temperature -pressure while in transit

Ensuring Safe warehousing Services

- Storage of Both Solid & liquid Chemicals

- Chemically compliant warehouse with HSE standards

- Custom Clearance: Handling the complexity of the norms related to the product

- Container de-stuffing and storage as per specific norms

- Order management and last mile delivery

- Record and MIS management

- Bagging and Debagging

- Silo Charging

- Quality Check at all steps

- End of Line Packing, Labeling

- Customized Palletization

Please click here to view the detailed brochure for our supply chain solutions for Chemical

For more details, please send email at chemical.lho@tciscs.com